Optimizing Production and Asset Management with Advanced Tracking Technology

In the fast-paced manufacturing sector, efficient management of machinery, equipment, and tools is essential for maintaining production schedules and optimizing operational efficiency. Tragging LLC’s asset tracking solution provides comprehensive visibility and control over all manufacturing assets, facilitating a more streamlined and productive manufacturing process.

- Industry-Specific Features

- Integration with Manufacturing Systems

- Reliable Support and Training

- Compliance and Risk Management

features

Emphasizing Precision and Real-Time Data

and Barcode Tracking

Monitoring

and Barcode Tracking

Precise and efficient asset tracking for streamlined manufacturing operations.

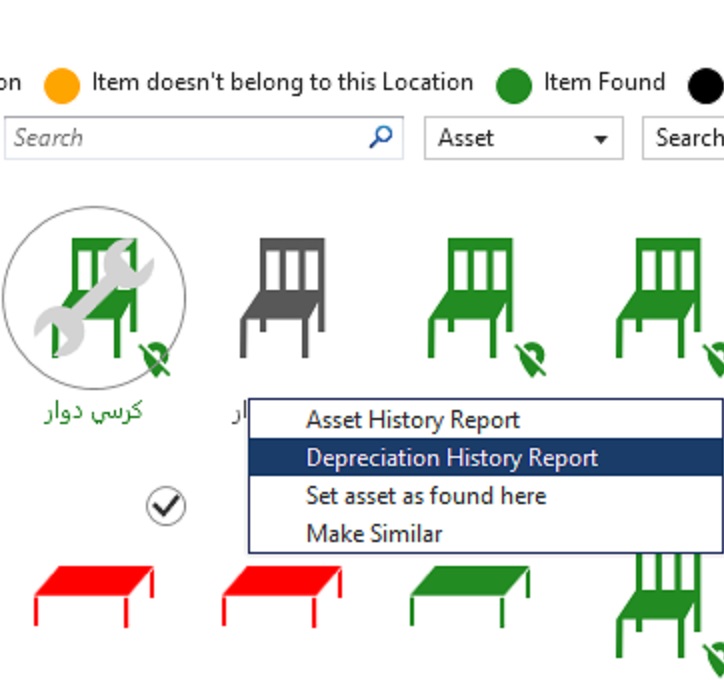

The system employs state-of-the-art RFID and barcode technology to provide precise tracking of manufacturing assets, from raw materials to finished goods. This technology enables quick and accurate inventory checks, reducing manual counting errors and saving valuable time.

Monitoring

Instant visibility into asset location and status for optimized production flow.

Gain instant visibility into the status and location of every asset in the manufacturing process. Real-time monitoring allows for proactive management of production assets, ensuring they are always available and operational when needed, thereby minimizing production delays.

Proactive asset care to minimize downtime and extend equipment lifespan.

Our system automates the scheduling of maintenance and servicing for manufacturing equipment, helping to prevent unexpected breakdowns. By keeping machinery in optimal condition, the system helps to prolong asset life and ensure continuous production flow.

Tailor the system to your unique manufacturing workflows and asset types.

Tailor the asset tracking system to meet specific manufacturing needs with customizable asset categorization. This feature allows manufacturers to organize assets in a way that aligns with their production processes and operational structures, enhancing asset management efficiency.

Streamline data flow between asset tracking and your core production systems.

Seamlessly integrate Tragging LLC’s asset tracking solution with existing manufacturing management systems, such as ERP (Enterprise Resource Planning) and MRP (Material Requirements Planning). This integration ensures a unified approach to asset management, aligning it with overall production and operational goals.

Benefits

Maximize Asset Value with Advanced Tracking

Maximized Asset Utilization

Tragging LLC’s system empowers manufacturers to gain a comprehensive view of how assets are utilized within the production process. By tracking and analyzing asset usage data, the system helps identify underutilized assets, optimize their deployment, and reduce unnecessary downtime. This leads to a more efficient production workflow, ensuring that every asset is used to its full potential, contributing to increased productivity and operational efficiency.

Preventive Maintenance Scheduling

The automated maintenance scheduling feature of our system ensures that manufacturing equipment is maintained regularly and remains in optimal condition. By predicting maintenance needs based on usage patterns and historical data, the system helps prevent unexpected equipment failures that can lead to costly production halts and delays. This proactive approach to maintenance not only extends the lifespan of equipment but also maintains consistent production quality and throughput.

Inventory and Supply Chain Optimization

Real-time tracking of inventory and assets is a cornerstone of our solution, directly impacting supply chain efficiency. Manufacturers can accurately monitor the flow of materials and components, adjusting procurement and production plans as needed to meet demand without overstocking or running into shortages. This optimized inventory management leads to smoother production cycles, reduced storage costs, and improved responsiveness to market changes.

Quality Control and Compliance

Our asset tracking system plays a crucial role in maintaining high standards of quality and ensuring compliance with industry regulations. By meticulously tracking manufacturing assets and processes, the system supports quality control efforts, ensuring that products meet strict industry standards. Additionally, the comprehensive reporting capabilities facilitate compliance with regulatory requirements, making audit processes more manageable and less resource-intensive.

Frequently Asked Questions

Asset Tracking in Manufacturing

- Q: How does asset tracking lead to maximized asset utilization in manufacturing?

A: Tragging LLC's system provides detailed insights into asset usage, identifying underutilized equipment and ensuring that all assets are employed to their full potential. This analysis helps streamline production workflows, minimize downtime, and enhance overall operational efficiency.

- Q: Can Tragging LLC’s system handle the preventive maintenance scheduling for diverse manufacturing equipment?

A: Yes, our system is designed to automate maintenance scheduling for a wide range of manufacturing equipment. It tracks usage and performance data to forecast maintenance needs, ensuring equipment is serviced at the right time to prevent breakdowns and extend lifespan.

- Q: How does the asset tracking solution optimize inventory and supply chain processes in manufacturing?

A: By providing real-time visibility into inventory levels and asset locations, our system helps manufacturers efficiently manage their supply chain. This ensures materials and components are available exactly when needed, reducing overstock or shortage scenarios and aligning inventory levels with production demands.

- Q: In what ways does Tragging LLC ensure quality control and compliance in the manufacturing sector?

A: Our asset tracking solution facilitates strict adherence to quality standards and regulatory compliance by maintaining detailed records of manufacturing processes and assets. This documentation aids in quality control checks and simplifies compliance with industry regulations, enhancing the integrity and reliability of manufacturing operations.

- Q: How does Tragging LLC’s solution enhance security and prevent asset loss in manufacturing environments?

A: With advanced RFID and barcode tracking technology, our system offers robust security features, monitoring asset movements and alerting management to any unauthorized access or anomalies. This not only helps prevent asset theft and loss but also ensures that sensitive equipment and materials are safeguarded against misuse.